When it comes to cooling enclosures, heat pipe technology is a no-frills, high-performance option that requires only fans for air circulation.

It is highly suitable for things or appliances that need an enclosure (sealed) but have power supplies that have limits. Since the noise output is minimal, you can employ these devices in otherwise noisy environments.

What are Heat Pipes?

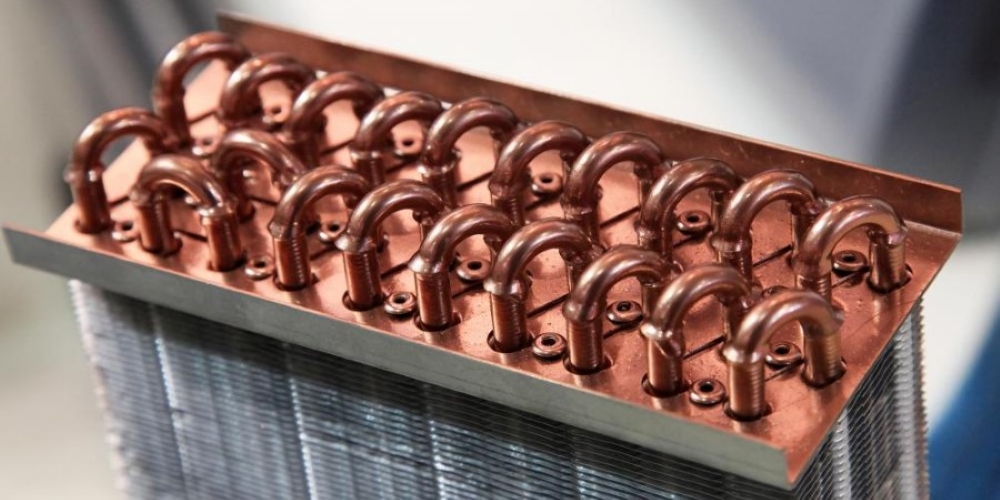

Compared to more traditional methods, heat pipes can expedite the movement of heat and energy by a factor of a few hundred. A common form of the heat pipe is a cylinder with a hollow interior that contains a vaporizable liquid.

It's not uncommon to see heat pipes in appliances like refrigerators and air conditioners and heat exchangers, transistors, and capacitors.

A high-performance copper heat pipe cooler is an outstanding illustration of a heat pipe. It helps lower the internal temperature of desktops and laptops, hence improving their performance.

How Does a Heat Pipe Operate?

A heat pipe is an aluminum-finned, vacuum-sealed tube that transmits heat more efficiently. A small amount of refrigerant exhibiting acceptable qualities at ambient temperature replaces the air previously contained within the pipe.

When first introduced, the refrigerant is liquid at the tube's base. By absorbing the heat of the hot air forced over the bottom of the tube from the enclosure, this liquid evaporates and rises to the top of the tube, cooling the air around the bottom.

Vapor in the tube condenses back into a liquid when its upper end gets exposed to the more excellent air outside. It causes the vapor to release heat, which warms the tube's cap. The metal fins carry this heat away to the atmosphere. The liquid condenses, sinks to the tube's base, and the cycle begins again.

Benefits of Heat Pipe Technology

Benefit#1: No Filters

Due to the clever layout of the outside air ducting system, we can forego using any filters at all. The only regular upkeep is to clean the fan's blades and the ambient air fins.

These units are appropriate for use in locations where regular access for maintenance presents a challenge, as the absence of filters eliminates a common cause of enclosure cooling maintenance issues.

Benefit#2: Long Lasting

Heat Pipes contain no moving parts. Therefore they won't degrade with time. As a passive component, the Heat Pipes are not actively doing anything. They are entirely static. The Heat Pipes can be provided with a corrosion-resistant coating if desired.

There are several different charged circuits woven into the fabric of the Heat Pipes. There is no reason for these to leak under typical conditions of use. There would be minimal impact on performance due to a large number of redundant circuits.

Benefit#3: Less Energy Usage

The energy required to evaporate the refrigerant comes from the heated air within the enclosure. Hence the Heat pipe itself consumes no electricity.

It uses a little fan to pull hot air from the electrical enclosure, direct it over the finned tube, and then return the cooled air to the electrical enclosure, increasing overall efficiency.

To hasten the heat dissipation process, a fan is placed outside and directed towards the hot end of the heat pipe. An air-to-air heat exchanger using a temperature differential of 10 °F may remove 400 watts of heat from an enclosure while using less than 60 watts of power.

Benefit#4: Flexible Size

Heat pipes can be more space-efficient when we compare them to others. Their versatility gets further enhanced by the fact that they may come in a wide range of sizes.

There is also the possibility of a shallow depth for heat pipes. It is possible to create a six-row heat recovery heat pipe with a thickness of only 8 inches.

Conclusion

There are many benefits of utilizing heat pipe technology. You will find the top benefits above Here we conclude our article on heat pipes. However, you can let us know in the comments if you need further information. Stay tuned for more informative articles.